What a contrast of operating philosophies I have experienced these last few days. People who write blogs tend to get treated differently than a typical user. In truth though what I am is a typical user who also happens to find value in information exchange and this blog is an effort to appraise others of my personal experience with software in use here. Comments on things in the CAD CAM world in general are of interest to me too and so there are comments on these as well at times. Industry trends and software and cloud paradigms will affect what our industries do and our bottom lines for some time. Looking on the web for actual user experiences and forum posts was a research tool for me and was pretty important in helping make decisions for every purchase but one. It is my intent to spur debates about the industry and to also inform potential buyers of pitfalls waiting for them. Or on the flip side that which has worked well and is worth looking into further. As an aside here. I don’t talk much about SE any more for a number of reasons but I still consider it the best and use it all the time. Sadly they are condemned to float along in relative obscurity because Siemens EX UGS people don’t care much for them so if you have a look remember this.

With CAMWorks for Solid Edge I was one of the driving forces behind getting Solid Edge to acquire a CAM partner that would truly integrate with SE. My stated preference years ago was for HSMWorks to also be “HSMEdge” but such was not to be when Autodesk got in there and changed the ball game. So even though I thought CAMWorks was second-rate compared to HSM I was compelled to support CAMWorks for SE because it was the only integration for SE out there and after all this is what we worked for. The rest is history and the CW4SE users, the very few of us that exist, rue the day we jumped on board.

So back to my lead-in sentence. Followers of this blog know how many months it has been since CW4SE users and this author have been told anything about CW4SE. We beg, we plead, we try going to different places online making comments in an effort to change things for the better and to try to even find out what the heck is going on. Neither Siemens SE or Geometric who are completely aware of the abysmal failure to deliver a competent working product respond. We clearly do not matter to them.

Earlier this week I was having a licensing problem with Inventor Pro HSM. I was a little bit surprised at the problems and went to my VAR after trying to fix it on my own. We both were scratching our heads over this. So I decided to do a little post on it. After all what I run into others will to and so I write. Much to my amazement about twenty minutes later I am contacted and the problem is quickly resolved. So here I am with three different software companies in current maintenance in my shop and the only one who seems to care about this users outcome is Autodesk. Now in defense of SE when similar issues have come up they have responded although never with the alacrity that Autodesk did this week. In the area of Geometric’s CW4SE though Siemens SE has cast us to the wolves and has had nothing to say to us for many months. Geometric has not spoken to users for 35 weeks now.

But we will now get to the main topic which is Geometric and the spreading miasma of failure which is bleeding over into the SolidWorks side to. I don’t need to say a whole lot about the problems over there on the SW side because the SW users there do it so well on their own. This will be a bit of a read but if you are considering any Geometric product you need to go through it all. Geometric’s forums are closed for a reason I figure. Autodesk CAM forums are not and that too is for a reason. One works one does not. In any case here are some current posts going on in the Geometric CAMWorks forum. While Geometric forbids people who are not customers from going there they do not say quotes of content can’t be made so I quote in its entirety two topics. The first one I had to chuckle over as a sort of gallows humor but in reality there is nothing funny about the situation. “Between A Rock And A Hard Place” was how the SW user started off.

“A rock and a hard place

Home – Program Smarter, Machine Faster › Forums › User Forums › General › A rock and a hard place

This topic contains 15 replies, has 8 voices, and was last updated by Dave Ault 1 minute ago.

Viewing 15 posts – 1 through 15 (of 16 total)

1 2 →

• Author

Posts | Subscribe Favorite

• March 26, 2015 at 4:49 PM #37409 Reply

PPC Engineering

Participant

Topics Created: 26

Replies Created: 95

I don’t know what to do with this software anymore. I manage a small CNC job shop which runs mostly small to medium sized lots with occasional prototyping requirements. I need to be able to release jobs to the floor as quickly as possible since my operators are done with their current work so quickly. CWx is supposed to make this happen but the software continually fails in every attempt to make programming quick and easy.

The techdb is a great idea but I don’t have the patience to keep rebuilding it, since every release of CWx that requires a techdb import corrupts something and makes me start from scratch. I’ve also noticed that, when saving new features to the techdb, it saves things that are not later accessible through the Access interface. I saved a groove operation to work the way I normally do grooves, but had included Z limits on the particular part I was programming, and it saved the Z limits to the techdb operation. Not a big deal, right? Well you can’t access the “advanced” tab options in the techdb so now that feature gets inserted with arbitrary Z limits every time I use it. Easy to fix by simply re-saving it, but why make it work that way in the first place? Big time saver there.

Need a post for a machine? Oh, your VAR will send you a generic one that MIGHT do what you want it to. More than likely they’ll tell you that you have to pay to have one made because they don’t have posts for very many machine types and they don’t support the post processor. CWx is supposed to be a top tier CAM software…who can’t supply a working post processor for any of the major machine builders out there without having to pay extra for it? I can list 6 other software packages that will provide them free of charge when you buy their software, but not CWx. Guess how I know who those 6 software packages are?

AFR is a joke unless you’re dealing with basic holes, and even then it doesn’t seem to have the ability to recognize tapped holes automatically. Anything other than the most basic pockets are quicker to insert manually than to let AFR try to figure it out. No time savings there. I’ve given up on trying to fix what CWx inserts automatically. 9 times out of 10 I end up deleting the AFR features and inserting my own so it isn’t even worth letting it try. Time out of my day.

CWx has LOST ITS MIND in the last few releases with turn mode. First of all, does anyone else find it incredibly aggravating that you can’t turn off the chuck display in simulation? I don’t want to see it. Give me the option to turn it off. Nope, now I have to manually open the turn setup, click a check box to enable me to edit the chucks location and manually input a value to move it out of the way. Thanks CWx, you saved me a lot of time there! Second, CWx has lost all ability to associate features properly. I can model a part to be turned, insert a turn feature, select the segments I want to machine, build the features then hit rebuild and watch CWx select its own segments, delete any extends I have selected, create random joins in the middle of the part and ultimately destroy what I created. Any time I make a change to ANYTHING its like starting at the 50% mark when it should be like starting from the 95% mark. And that is IF it retains its feature associations. I just modeled an expanding mandrel for a fixture I am designing. I got the entire thing programmed and realized I wanted to decrease an OD thread diameter by 0.010″ to increase the crest amount. I altered the sketch, hit ok, clicked on the CWx feature tree, hit rebuild and EVERY…F***ING EVERY…feature failed to rebuild. I literally had to start over from 0% by simply changing a diameter by 0.010″. Thanks for all the time savings CWx.

When I bring these issues to their attention I always get the “We can’t reproduce this issue, please call so we can set up an online meeting to see the problem in real-time” message. I don’t have time to fix your software…I have a business to run. I can’t keep up because it takes me twice as long to program a simple part than it should. I spend my entire day scrambling to keep programs fed to the shop floor fast enough. The result? I work 12+ hours per day to try to get enough done to keep everyone busy. Stop spending your time and money (MY time and money) adding enhancements that don’t work and waste more time, and start testing your damned software across more platforms than just what you have in your office so it works when you release it. There needs to be a serious overhaul to this system. Release a lite version with the bells and whistles turned off so I can JUST PROGRAM PARTS efficiently. I don’t need to simulate my machine in 100% accurate detail if it means that my software can’t retain features. That is not a time saver. That is not “Programming Smarter and Machining Faster”. I don’t need a chuck in the way every time I program a part. I don’t need the ability to select from 12 different versions of every end mill diameter in the techdb. These are all great things to implement and would be appreciated if the core of the software wasn’t utterly broken.

The worst part of the whole ordeal is that we are teetering on the brink of failure trying to keep up with demand and I can’t do anything about it. If I stick with CWx I can basically expect to continue to spend all day at work trying to get programs done and keep just barely getting by. I can’t afford to buy another software package because of the situation we’re in. I’m stuck between a rock and a hard place and don’t know what to do anymore.

Geometric, for the love of god, please take a long look at the disaster you are perpetuating and take a step backward to fix it. There are so many people relying on your software to keep them moving forward and these forums (and others) are riddled with posts about broken functionality and problems preventing people from programming effectively. When is the last time a major CAM software RECALLED a version release??? Seriously, WHEN? It has gotten to the point that most people won’t even install a minor update until they’ve heard from more experienced users that it works (or more accurately, WHAT works). I update out of desperation…in hopes that eventually these problems will be fixed.

I’ve been patiently working through all of these problems for almost 4 years now. I’m sure I’m not the most efficient programmer to begin with, and probably don’t use every tool at my disposal to decrease programming time, but it amazes me that simple things are so difficult in this software. Am I the only person who feels this way? Can I get some support from other people who do, or am I just that bad at this programming thing? Someone, somewhere, needs to get this message through to Geometric. If ANY other integrated CAM system offered to buy me out of CWx I wouldn’t even weigh the decision…I would jump ship immediately. Sorry to those of you who don’t feel this way or don’t care, I just feel trapped in a downward spiral.

/rant

March 27, 2015 at 3:42 AM #37413 Reply

rainman

Participant

Topics Created: 19

Replies Created: 280

I agree in many ways. Seems like when a new version gets released, things that were already working fine become broken. They keep changing the UI, sometimes for the better, but it doesn’t really make it faster. I am having some trouble as well with 2015 in lathe, but mill seems to be working well. To turn your chuck display off, try clicking on the button for “fixture display” on the simulation palette and selecting “no display”.

March 27, 2015 at 4:31 AM #37415 Reply

Chris Cordova

Participant

Topics Created: 44

Replies Created: 273

You aren’t alone. My particular gripe is the rebuild. You can hit Rebuild all day but it won’t actually work until you open the feature and accept it. So if you have dozens of features it takes a fair amount of time. To be specific, if a a feature up to a face has changed I can’t reliably just hit full rebuild. I have to open it then rebuild. What’s rebuild for anyway?

The post issue you mention baffles me too. Sigh. I still have to manually edit my post when probing on my Haas. My Haas! A very common accessory on a very common machine and they had to write a post from scratch? Really? It’s up to a point that works mostly but I gave up trying to get them to fix it so I wouldn’t have to edit it.

Even with these gripes and others I have, not sure you’d find it different with other CAMs. I’ve glanced at some CAM forums and people are griping there too. I’m not saying this as an excuse for CAMWorks. They should get their act together.

OK, back to work.

March 27, 2015 at 4:36 AM #37417 Reply

rainman

Participant

Topics Created: 19

Replies Created: 280

Sad to say, but I’ve found the only way to make your posts work right is to make your own. I know everyone doesn’t have the time to do this, because in my case it took me quite a while to get decent at the code. I have some really good posts now, but it was a continual process over a couple of years. My VAR did try to help me early on, but I was having trouble communicating what I wanted. If I wanted something to come out a certain way under one condition, but another way under another condition, they just copied what I had on my marked up program listing and made it come out the same way every time.

March 27, 2015 at 6:06 AM #37421 Reply

Bob Bergeron

Participant

Topics Created: 1

Replies Created: 9

I do not see people on here reporting that they are regularly having problems importing the TechDB. We have never had that issue, thankfully, and have installed every new version since (almost) two decades ago. Since you have the problem repeatedly, I would think that your VAR would do the next update for you, to track down what is wrong. I agree that the work to scratch reconstruct even a single TechDB is unthinkable.

I see that your question about toggling the chuck display has been answered. However, I now find that having the translucent version of the chucks always displayed is my preferred operating mode. With the tight tool/chuck clearances we need to run on many dual-spindle mill-turn parts it is nice to keep aware of those jaws. My only gripe is that they still have not fixed CAMWorks ability to SAVE jaws with unequal step widths and depths – Geometric has confirmed the bug, but it has been tow SPs now without a fix.

It seems to me that CAMWorks is really only designed to shine in shops that have control over the SolidWorks models that the parts are coded from. We found long ago that s slight variation in how a lathe path (revolve) is built would make or break the quality of the AFR on that path. Same thing for multi-step holes, etc. For example, if the lathe path has ultra-tiny or overlapping (un-trimmed) fillets and chamfers, or broken segments, CAMWorks may give you unwanted Joins or other bad behavior.

I think Techsoft (now Geometric) knows how to code the SolidWorks parts with their “best practices” – so they never see these issues. If they paid more attention to users’ problems, I think they could harden the package against users’ different, but legal, approaches to modeling parts. That said, I have seen steady improvements over the years in what CAMWorks will tolerate – although at a rather glacial pace. Do be sure to only use Mfg. View – not the legacy AFR mode for recognizing features.

I use the save button after almost every little “milestone” operation I create and like. That is my “undo” button. I occasionally use the Operation’s lock toggle – for stuff I do not want CAMWorks to “fix”. But mostly, I have modified the TechDB to automatically code anything it can, the way I would do it manually. That is really the ONLY solution to LIKING rather than HATING CAMWorks. I do not think that the VARs or Geometric Support ever makes this point hard enough.

Perhaps Geometric and VARs feel that, if they do explain how you must setup and use CAMWorks, too many users (or potential buyers) will decide that the CAMWorks approach does not fit the type of jobs they code or how they like to work. However, for our shop the CAMWorks design-intent, even if not their execution of it, is exactly what we want.

Our engineers design our parts knowing CAMworks and our machine’s features and limitations. Our operators are not allowed to modify the code. If something is wrong it goes back to engineering for a model change, or coding for a CAMWorks fix and repost. When we make a CAMWorks “fix” we always evaluate if a change to the TechDB is appropriate, and if it is, we make it right then. In the beginning, it was awful – lots of idle spindle time. But eventually the method worked, and now such TechDB changes are infrequent.

We can now modify many already codded parts, sometime in many major areas, and have CAMWorks totally heal the code – without any significant manual intervention. Without significant time invested in the TechDB and posts, that was NEVER going to happen. It is a shame that Geometric (and our VAR at least) puts almost no effort into relentlessly evangelizing this fundamental user requirement.

March 27, 2015 at 6:30 AM #37423 Reply

rainman

Participant

Topics Created: 19

Replies Created: 280

Agree with all above. I struggled mightily with Camworks for some time, but after getting my TechDb the way I liked it, as well as the posts, I don’t have much trouble anymore. Yes, they do sometimes break things when a new release comes out that were working before, but it ends up being a matter of settling on the version that works best for you. No, it shouldn’t be this way, but I’m not in a position to tell my superiors that we need to buy something else now that we have 9 years worth of data created with Camworks. As far as “oddities” in turned parts, I don’t use the original design part. I make my own new part, then insert the design part. That way, if I want to add a cut, fillet, chamfer, or something to help the output, I can without changing the original part.

Don’t know why PPC is having the difficulty with importing prior TechDbs, since I have not. There must be an issue with his installation, but I wouldn’t know where to start looking.

Bottom line is, yes, Camworks is quirky, sometimes annoying, but if you get to know what it likes and doesn’t like, you can make it work for you.

March 27, 2015 at 9:47 AM #37429 Reply

PPC Engineering

Participant

Topics Created: 26

Replies Created: 95

In my system at least, turning the chuck display off in simulation makes the chuck invisible, but the tools all still crash into it causing a collision alarm. The only way I have found to get around this is to manually move the chuck away from the part. Is this not the way everyone else’s system works?

I have never been able to import an entire techdb without it destroying some part of it. I had an online meeting with a representative from my VAR the last time I updated, to help me import it properly. I backed up my old techdb in a zip file to be able to save all of the info just in case something went wrong. Not only did it corrupt the non-zipped version, but somehow whatever my VAR did was able to corrupt the backed up techdb INSIDE of the zip file. Unzipping the folder produced a corrupt database. We use Microsoft Access for a number of things here and the only reason I can see for me to have so many problems like this is some kind of mixup between versions of Access or .net framework. I can’t see that really being a problem since many companies rely on Access or other database software. Maybe I need to bite the bullet and do a clean install on a freshly formatted hard drive with Geometric overlooking to make sure it is all done correctly.

I just don’t have time, with all the hats I wear, to be able to muddle through every program I make simply because CWx has a problem with the way the part was modeled. If the resulting model is the same, why should I expect a different result?

Frustrated…

March 27, 2015 at 5:49 PM #37431 Reply

Ted Ellis

Participant

Topics Created: 11

Replies Created: 236

I do understand your frustration and the work pressures. All we can do is give our experiences. I’ve been importing techdb for years with some minor difficulties, but no serious ones. I will admit many many years ago when I had a custom one and they released a new version they pointed out that it had new 3 axis strategies and maybe other items that would not show up if I imported my techdb. So I did start over at that time using their stock one and have been doing ok ever since.

I recently posted about some oddities in our techdb not showing tools for the lathe even though they were properly entered. I sent my techdb to support and they repaired it successfully. Seems like something else is happening with your situation that should be solvable, but investing the time to do so sounds like it’s a challenge for you.

March 30, 2015 at 7:18 AM #37435 Reply

PPC Engineering

Participant

Topics Created: 26

Replies Created: 95

Time is certainly the issue. I am inside sales, engineering, programming, quality control, supervisor, estimating, purchasing and often times repairman. Regardless of that fact, it seems like there is so much that I shouldn’t have to deal with, that could be fixed up front to save EVERYONE the hassles that keep popping up here.

March 31, 2015 at 3:11 AM #37437 Reply

Chally72

Participant

Topics Created: 8

Replies Created: 38

Spot on post, for the most part….as I sit here waiting for a web meeting to ‘reproduce’ yet another problem they cannot. I’ve also been asked for part models, which I’ve supplied, because I ‘build models differently’ than they’ve seen/anticipate.

Here’s a link to my experience on the Solid Edge side of life:

http://community.plm.automation.siemens.com/t5/Solid-Edge-Forum/Current-State-of-CAMWorks-for-Solid-Edge/m-p/282673#U282673

Some of my favorites right now are the fact that features based off of sketch elements, like Open Profiles, disassociate EVERY TIME YOU CLOSE AND REOPEN THE FILE, and lead-ins on grouped features have nasty bugs that makes it almost impossible to successfully apply the lead in to all. Oh, and the software mixes up filenames and sometimes asks you to save a file with a name that existed several save-as events ago! Even though this doesn’t affect data integrity, it sure is disconcerting.

Solid Edge users are still waiting for SP1, which was supposedly going to be available to resellers pending final release in the first week of March. It’s exhausting trying to chase down information on what is going on!

o This reply was modified 2 days, 7 hours ago by Chally72.

March 31, 2015 at 2:12 PM #37443 Reply

Dave Ault

Participant

Topics Created: 2

Replies Created: 28

No Chally it is worse than frustrating. I have not used CW4SE since about the end of last November when I could not afford to waste more time. When the SP0 release came out and was also so buggy I just quit trying. The last straw was when I booted up SE and CW4SE, a program I had not used for months, decided once again to short circuit my SE license file. Geometric, this license file crap goes back to the very beginning of post on this forum. Is there any particular reason you are so inept that these kinds of things can’t be fixed once and for all?

It has been 31 weeks since SE ST7 was released and still nothing that works from Geometric. It has been 35 weeks since anyone from Geometric could be bothered to even tell us anything. I read of the years long continuation of problems and look at garbage Tech Data Base stuff put in there by cubical programmers before Geometric bought out Pro Cam that are still there that have never had a machinists input. You guys on the SW side are lucky to have prior work from the Pro Cam programmers in CAMWorks. Over on the SE side the Geometric guys who have had to do it all could not produce a competent working program if they had to. It is hard to imagine what must be going on in the minds of Geometric management that they can’t make something work and then can’t be bothered to tell us a damn thing about it. The very idea that it is considered acceptable to have to wrestle with a TDB that has so little basis in real shop practices for years to get it “right” blows my mind. Geometric, if they were worth a damn and competent, would make it so it worked out of the box in a suitable fashion and THEN you would improve on it to suit your needs. I can’t believe it was ever my misfortune to have become involved in this.

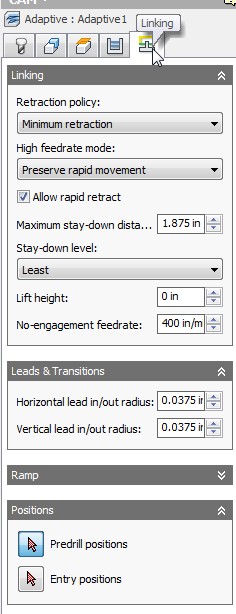

In self defense I have bought Inventor HSM. I was cutting parts quickly and easily and the Adaptive tool path is better than Volumill. Tool libraries are a simple create by tool entity you can save any way you want and tools are added in less than 60 seconds and edited in 20. I figure I will write years worth of CAM plans here in the time it would take to just set up the TDB and that does not count ongoing time and TDB failures which cost more time.

Speaking of probes how many times does the Renishaw probe say your .500 endmill is exactly that including the eccentricity that may be there with tool holding. Try dealing with endmill reality in the TDB when that .500 end mill is hardly ever that. Tell me how easy it is to work with this mess when you want accuracy. And by the way. Geometric promised me a lathe post so I bought lathe with the package. When I finally bought a lathe it was time to find out they are liars and had no intention of providing a post. Surfcam and ZW3D and HSM all have free posts that work and have worked in my shop. I’ll tell you what. It is time to just quit. The more I write the madder I get at this incompetent bunch employed by Geometric.

o This reply was modified 1 day, 19 hours ago by Dave Ault.

April 1, 2015 at 4:16 AM #37447 Reply

rainman

Participant

Topics Created: 19

Replies Created: 280

Wow, I had no idea that things were so bad on the SE side. I’ve had my beefs with Geometric over the years as far as buggy first releases, and things that used to work being broken in major releases. However, I’ve learned to use it and avoid the pitfalls. I’m sure there are better packages out there, but I’m entrenched too deep to do anything different now, and it is working for me, despite issues now and then. I don’t blame you, though, for wanting to jump ship. I would too if things were that bad on the SW side.

April 1, 2015 at 2:22 PM #37449 Reply

Dave Ault

Participant

Topics Created: 2

Replies Created: 28

Yes it is bad. New motto for Geometric might be… ” If you want to be beaten black and blue Geometric is for you”. To top it all off they did not co-ordinate with Siemens to get needed API changes in the queue In a timely fashion. Like a company that worked with integration partners would have. They ignored problems until to late and now it will be ST9, another year and a half, before some important stuff might be fixed. I say might be because I don’t think the talent exists with Geometric to integrate with SE. I base this on what they have done to date. I base the timeline on the fact that ST8 is already in beta testing and there will be no changes for an outfit like Geometric that could not get in line in time. ST9 is the very earliest serious issues can be fixed.

These Geometric people actually had the nerve to say problems that crippled the software was intended behavior until we made a big stink with Siemens about Geometric. Then they became problems that were on the fix it list. Why in the world would I ever be interested in doing business with Geometric in the future when their attitude here was to ignore us until they were forced into having to look into it. The song and dance the OP references above indicates to me Geometric either is to incompetent to even find problems or so underhanded that they intend to just stonewall the problems until we go away. BUYER BEWARE.

April 1, 2015 at 4:34 PM #37451 Reply

PPC Engineering

Participant

Topics Created: 26

Replies Created: 95

Wow, I guess I shouldn’t complain hearing how bad you guys have it. Kind of sad, the failure stories are becoming the benchmark for CAMWorks users, not the success stories. I don’t remember the last time I heard anyone say “CAMWorks saved me $_______ due to its features and interface…yadda yadda yadda”. The most recent “Success Story” I can find with a date on it says 2013.

GEOMETRIC, Listen to your users and go back to basic reliable functionality! Save the advanced features for the beta testers until they have been shown to work across multiple platforms and user environments!

EDIT: I, also, am looking at HSMWorks integrated with SWx. It is not as advanced but the user interface is friendly, easy to use and JUST PLAIN WORKS. Not to mention the posts can be edited in ONE FILE using javascript. Tougher programming language, MUCH simpler to make a post do what you want once you know it.

o This reply was modified 17 hours, 46 minutes ago by PPC Engineering.

April 2, 2015 at 7:24 AM #37457 Reply

Dan Peters

Participant

Topics Created: 6

Replies Created: 46

We ultimately had to switch our wire EDMs over to Esprit and will be doing the same for the new Integrex we bought. I think Camworks testing department is the end user. I find it to be true about the post in that they are very generic and the end user has to spend a lot of time and leg work with them. If you have to pay for a post that should be done up front by the software company. It will be interesting to see how Esprit does with our new Integrex. We could never get Camworks to work well with our old Integrex and ultimately gave up. As far as our mills it has not been the worst, I found that keeping away from the new releases helps immensely.

o This reply was modified 2 hours, 56 minutes ago by Dan Peters.

• Posts | Subscribe Favorite

• April 2, 2015 at 10:22 AM #37467 Edit | Reply

Dave Ault

Participant

Topics Created: 2

Replies Created: 28

“EDIT: I, also, am looking at HSMWorks integrated with SWx. It is not as advanced but the user interface is friendly, easy to use and JUST PLAIN WORKS.”

You have that right! Instead of heart burn and constant anger today it can actually be kind of fun again. I enjoy this line of work when unnecessary complications do not rear their ugly heads. CAMWorks 4 SE took all that enjoyment away when I had to use their program.

At this time I can only conjecture that this is a company in way over their heads and in turmoil over their inability to solve the problems. It looks like they took on this new machine verification and the new SE integration along with the continuing SW product and have not provided enough talent to do it all. I have a picture of the Keystone Cops running from place to place in panic. I know they hate to spend a dime on anything so I wonder how many cheap programmers they have never understanding that numbers do not equate to quality as an end result. Cambridge and MIT are world leaders in CAD and CAM innovation and problem solving but they are not cheap. It all depends on the value you place on what your customers can expect from you. If you populate your company with programmers that can’t do the job you get a result like Camworks that is slowly sinking into the quagmire.”

The second one also touches on my top pet peeve with Geometric’s nasty habit of sending out software without testing it. It is impossible for a company that cares and has a qualified testing procedure to fail like Geometric regularly does so therefore I maintain they have no qualified testing lab or department and no desire to create one to date. Problems on the SW side seem to be accelerating in frequency and severity with CAMWorks 2015. As you will note these guys also complain about hearing nothing from Geometric about their problems. Geometric has a total disconnect from their customers in every way except for asking for money.

“SP1.0 Backward Compatibility Problem

Home – Program Smarter, Machine Faster › Forums › User Forums › General › SP1.0 Backward Compatibility Problem

This topic contains 3 replies, has 2 voices, and was last updated by rainman 8 hours, 35 minutes ago.

Viewing 4 posts – 1 through 4 (of 4 total)

• Author

Posts | Subscribe Favorite

• March 24, 2015 at 5:20 PM #37407 Reply

Bob Bergeron

Participant

Topics Created: 1

Replies Created: 9

We just upgraded from CAMWorks-2015 SP0.1 to CAMWorks-2015 SP1.0. Now we have found that when trying to open many (a little over 10%) of our existing SP0.1 files in SP1.0 it wipes out all the CAMWorks data from the files. We have turned to our VAR, but they cannot get CAMWorks-2015 SP1.0 to open these files either. Since we cannot do a parallel installation of SP0.1, like we could for different year version s of CAMWorks, we are in a Catch-22 now. We already codded many new jobs under CAMWorks-2015 SP1.0, so uninstalling and going back to SP0.1 is not a practical option either.

Has anyone else run into this yet? If so, have you found a solution?

March 27, 2015 at 3:35 AM #37411 Reply

rainman

Participant

Topics Created: 19

Replies Created: 280

Going back to SP0.1 should not cause you to be unable to open ones created in SP1.0. Normally, only full versions (2013,2014,2015) cannot be opened in a previous version. Service packs within a year version should be interchangeable. Sounds like you have a serious bug… wonder if it’s global or just your situation. I was about to install 1.0 (have to wait for IT to do it), but I’m wondering if I should wait, now.

March 27, 2015 at 5:07 AM #37419 Reply

Bob Bergeron

Participant

Topics Created: 1

Replies Created: 9

Thanks for replying. I got this same information yesterday morning from my VAR’s third support guy – and uninstalling SP1.0 and reinstalling SP0.1 fixed it! Amazingly the first two support techs, and Geometric’s support did not correct me about the ability to uninstall SP1.0 and reinstall SP0.1!

It is certainly a big deal. So many different parts on so many different support-techs systems duplicated this problem that is is hard to believe that many will not have this same MAJOR issue. I imagine the fix is simple, but it has been days now without any news from Geometric!

April 2, 2015 at 5:14 AM #37455 Reply

rainman

Participant

Topics Created: 19

Replies Created: 280

By the way, has anyone else experienced what Bob describes here? I’d like to install SP1.0, but not if it does this…”

Geometric I once again open this forum which I know you read to your commentary. Is there ANY interest by anyone over there to clarify what is going on? Some day you are going to have to talk to people about all this. Well maybe not. Perhaps your solution is to wring your hands in despair as your company sinks into the relative oblivion heading to it if you don’t mend ALL of your ways. It won’t be the first time a company goes belly up.