Autodesk is pretty tight mouthed about what will be new and when it will be out. It is around the corner though and I suspect that within the next week or two will be released. There are some serious code changes under the hood that are taking place and it, like all ambitious coding projects seem to be, is garnering delays in release of product.

What I have heard is the long-awaited Hole Wizard may not happen soon. I don’t know why but none seem to want to talk about this in terms of soon or finished. Lathe seems to be taking a back seat to four and five axis milling and some new people are coming on board to help with this including some exceptional four and five axis post talent. I have been told that this represents a bigger market than Lathe which personally I find hard to believe. I am not privy to numbers though so what do I know eh? Four and Five axis is an area that needed help though and it is on the way.

Something which I have seen but have not had any pictures forwarded to me to share is Probing for we lucky owners of Haas CNC mills that have the Renishaw probing on them. Haas probing which is as far as I am concerned is the best single option offered in the industry besides the inherent speed of cutting possible on whatever equipment is purchased from any one any where. If you buy a Haas mill and do not get probing you are crazy. Adding to this value for HSM users is the upcoming HSM ability to probe many different shapes and features way beyond what many do. Haas probing comes with a great Renishaw program but you have to learn the macros to use it with. HSM probing as I gather will take ease of use for the probes to a much higher level. I don’t know about you but anything that makes my life easier with the avoidance of having to learn yet another programing routine is welcome.

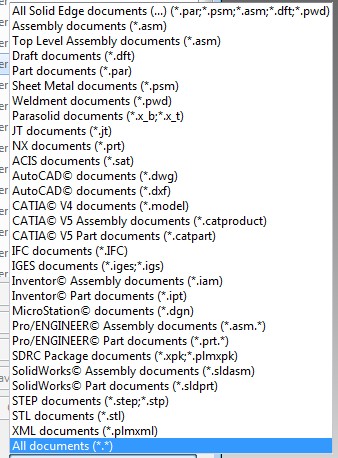

For Solid Edge users we will finally be a part of Inventors AnyCAD importing capabilities. At this time I have seen some associativity with parasolid files I have imported auto updating but this has been very spotty. With the advent of direct recognition of SE .par and .asm files this bottleneck will be gone.

There is behind the scenes co-operation between machine manufacturers and cutting tool manufacturers and HSM that will become evident this coming year. Personally I am excited about these upcoming partnerships and improvements because in spite of my outright hostility to subscriptions the power of HSM has been proven in my shop to my satisfaction. Anything that improves this great tool of production to a higher level is icing on the cake served every day I cut parts in my shop. Adaptive is the engine behind this as it is the single best high-speed machining program out there and forward-looking companies are getting involved with HSM because of this.

Funny thing about HSM adaptive. My friends shop bought into Delcam Partmaker for turning because HSM could not do the multi-axis work to their satisfaction on their new Okuma. I am always curious about programs and talked to Delcam about turning. At the same time the sales shmuck waxed eloquent of the common gui between all aspects of Partmaker so I asked about milling and specifically high-speed machining. Gave them a part and five specific screen captures of areas I wanted to see tool paths on. I was sent one screen capture of a boss with a cavity on top and the other four areas were ignored. The Delcam tool path did not get to the bottom of the top boss cavity. I responded and asked why and where were the other areas of interest and no response. I figured if they had something to show me they would have. Just like Volumill and CAMWorks it appears Delcam Partmaker evidently could not equal the efficiency of HSM Adaptive. I have yet to see anything else that does.

I have no doubt there are many new things upcoming but like most of us I have to wait and see. I have found beta testing to be more trouble than it is worth and don’t seek the “thrill” of exposure to a program before it is RTM anymore. CAMWorks cured me of any desire in this area. Autodesk is reticent to talk about things ahead of time and I can understand that to. The poor HSM guys for instance get hammered when things don’t happen just as they predicted and these choices are not exactly under their precise control. You get beat up often enough you quit talking and making promises and so we get the waiting game. It will be over soon though and I for one look forward to good things to talk about.