As a blogger you get information with admonishments not to talk about it publicly. It is the curse that goes with the territory and you have to obey it or run the risk of losing information sources. But the plus side is that sometimes even though you can’t talk about the information in exact terms by repeating verbatim what you were told and who told you, you can use this to connect the dots. Ever wonder why people and companies do things that make no apparent sense? Ever wonder why policies that should be enacted that are just common sense to you and I who are potential or actual customers never see the light of day? Ever wonder why someone like myself who two years ago was the largest SE blogger in reader counts outside of official bloggers on a VAR or Siemens payroll has had such a drastic change of heart? I look back on some of my posts and they would easily fit the label fanbois and I meant every word of it. I was and still am a huge fan of the software but most definitely not of its current leadership or owners. So rather than sitting here and getting ready to eagerly depart for another SEU I sit here as I write this Sunday morning and reflect on what is and what could have been.

The departure of Karsten Newbury and Don Cooper was the seminal beginning of the end for SE. It was the public face of the actual intent of Siemens to sideline the future of SE. I tend to believe the anti Solid Edge sentiment and deliberate sabotage of SE by UGS individuals is true and these guys being forced out was the signal the UGS side had won.. I have heard it to many times from different people in different ways to not believe so. I also happen to know that Karsten and Don had dreams and goals and they were the same as mine. For SE to take its rightful place in the MCAD world as the premier program both in capabilities (which were there by ST5) and in actual market share. We discussed this fairly often so I believe fully that they had a vision.

But you see Siemens is tailor-made as a company for chicanery and politics over what is right or wrong or meritorious and the UGS guys were in heaven with the chance to finally kill the SE threat. The same SE that gives them some sheet metal capabilities and Synchronous Tech that they had to buy and did not come up with on their own. Siemens is a company full of dead wood and people who thrive on meetings and reports because they can pretend they are earning their wages by doing so. Politics and back stabbing as a primary method of advancement over real capabilities with concrete results and merit and the modus operandi of doing nothing means you stay below the radar thereby getting paid handsomely to do nothing. A bureaucracy which has been told for years that this is the right way and the Siemens way because none ever seem to get fired for doing this. It seems as though once you get hired on you stay as long as you wish no matter how bad you are. Just don’t rock the boat. Don and Karsten had to go because they were innovators and believed in rocking the boat when needed to get the work done. Look at the profitability of Siemens overall compared to their manufacturing peers and see the results of this philosophy. These then are the qualities of the Siemens hands that hold the future of SE with malign intent as we head into SEU 2015.

Mark Burhop was the first developer that I knew of to be snagged from SE and not replaced. The plunder of qualified individuals from SE then going to the NX side is revealing. Mark like the others I have met in Huntsville was dedicated and top-notch. It is hard to replace people like this and if you care you have to bring the replacement up to speed and prove them out before you send off the good guy. This is not being done with inevitable results. CAMWorks and I have had some serious disagreements on what was and should be done. During some of these discussion I had with Geometric USA I was told that they had wondered why there was so little co-operation from the Siemens side of things.

Thinking about this after some information I received this past week gave me another connect the dots dot.

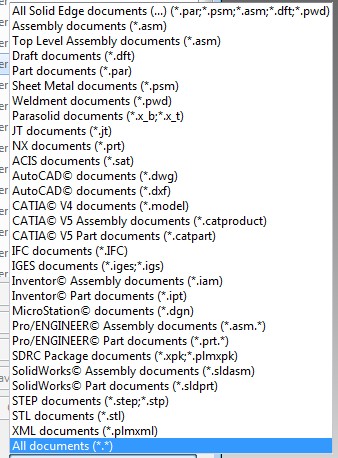

Notice the import capabilities of Inventor and Solid Edge. Solid Works has proven the model of allowing others to integrate and work with and establish a large ecosystem of applications that can be used in conjunction with SW. Not so much now that the corporate hand of Parisian Dassault tunnel vision has decided to slowly kill them off but it is part of what made them #1. Inventor and Autodesk work with others and they see the value of this community building process. I have to believe that the inclusion of Inventor import capabilities into SE and the lack of SE direct import capabilities into Inventor is not by accident. Look also at the age of SE compared to Inventor and think about the number of integrated apps. I think about the problems I knew of with CAMWorks and SE and I conclude that there is no desire to co-operate from the Siemens SE side. I knew the philosophy of Cooper and Newbury and this is not from them. It is not a legacy from them. It is one of the things they had to fight against and is one of the things in the end which caused them to be run off from Siemens. Was I there in the boardroom meetings when these decisions or policies were being laid out and down? No of course not. But I can see results of the decisions made and I did not have to be present to know what was decided. I can just look around and connect the dots and know I am right. The policy of Siemens towards others and SE is screw you unless you want to play NX and screw SE users too.

ST7 was the peak for SE with practical user capabilities and the logic of the GUI. ST8 saw gimmicky things like Surface Pro integration as the new feature leader. Something not asked for by many but there anyway. It is the SE equivalent of the year SW added two rendering apps. It is what companies do when the innovation is gone but they feel compelled to add new things. People do expect new things after all when you expect them to pay each year and they no longer need support. For me ST8 brought nothing much new to the table I needed and it changed the behavior in ways that have complicated my life especially in assemblies. Change for the sake of change by moving things and changing how things work is a simple easy way to present the facade of new and different. Without of course making your developers come up with revolutionary user first and foremost changes. It is what companies do when they are not intending a bright future for a software program and or have lost the desire to give you full value for your money and loyalty.

Talking to an Autodesk guy in Nashville some months back. He used to work for UGS on the NX side. Hearing the words Red Headed Stepchild applied to SE from his mouth first and not from my prompting was a bit of a shock. In discussion he told me this was a common perception amongst the hoity-toity UGS NX side of things when he worked there. I hear this so much from people exposed to the UGS NX side of things and I can’t deny the actual results of this mindset I see in action. The anti SE mindset of PLM World brought to you by their members and leaders who are almost to a man UGS NX Teamcenter etc and with them the comes the pervasive UGS leadership attitude.

Another Siemens NX UGS beat on SE story happened when I was on a job recently. Met with a guy who really knows his stuff and he told me that one of the premier sheet metal developer guys from SE had just been snagged by NX. Another developer gone and not replaced and sheet metal is outside of ST perhaps the single most powerful part of SE and highly regarded by its MCAD competitors. It is all I hear of now. People being taken away along with budgets from SE. I remember going to Huntsville a few years back and these dudes were on top of the world. Cooper Newbury had made available funds and told these guys to hire more help and make SE the best. The despondency down there today would have to be seen to be believed. I think I would go to the NX side of things too if I were them and had the chance. The hand writing is on the wall for SE in so many ways.

How about that new guy Siemens has for SE. What a spark plug and whirling dervish of Solid Edge enthusiasm he is. OK so you don’t know who he is and I am not surprised since he does not have a vision and a desire to communicate. The only public commentary supposedly by him on the Siemens SE forum or indeed anywhere else since he became Siemens place holder for the position was written for him. He did not write and evidently had no desire to do so. The Publicity and marketing idiots over there felt they had to do something anyway since Mr New Big Guy did not care to and they wrote for him and posted it. Here it is and note the badges earned by this guy. Register and write once and respond once and you get this.

Here are Karsten’s SE forum stats. I can also tell you from personal experience that Karsten and Don monitored the forums for user problems and behind the scenes did things about what they could while fighting with Siemens to do the right things.

Here is the Siemens place holders stats. I have no idea what this guy does and neither does anyone else. No one sees him and no one hears from him. Of note here is the PLMCONX15 badge. It means he attended a Siemens PLM mucky muck deal with no relationship to SE. I suppose this is the place where earlier this year Siemens decided with a one week notice to roll out ST8 at an event not related at all to SE and where no SE users were in attendance or even had a chance to plan to go if they had wanted to. Another little indicator of the contempt Siemens UGS holds SE and it’s users in.

According to the agenda for SEU2015 as of Sunday morning Mr Spark Plug is scheduled for 15 minutes at the very beginning only and that is his sole appearance for the event.

My big question where he is concerned if he even shows up at SEU 2015 which I think is debatable would be is he another teleprompter empty suit kind of guy. Or will his true passion for SE finally be displayed with a masterful extemporaneous dissertation on his vision and passion for the SE future. Sarc purple script button now off for those of you who may remember this :-). Like Siemens Miller is multilingual and his favorite French Dassault sponsored word he shares in common with Siemens for describing SE users is BIOYA.

Autodesk please buy up SE too!! HSM and SE would be a match made in heaven and SE deserves to be in hands that appreciate what it is.