Recently the overlords of the official Klipsch sponsored forum have gone a bit wonky on what they allow. Apparently the idea that things like my tweeters are called upgrades really irritates some Klipsch people and so they have been deleting some tweeter threads and comments along with other threads on different topics that also irritate them. I have no idea what prompted all this but find it somewhat ironic.

Roy Delgado is the chief engineer for Klipsch and he does admirable work. I have nothing but high regard for his technical abilities but his involvement in the forum has not been so productive. Very sensitive to the idea that thirty year old drivers and horns have been improved upon and are far better then those old dog barker tweeters Klipsch used for way to long. He talks about preserving the PWK legacy and vision and sound but has done things like convince PWK to start using Tractrix horns so he himself is guilty of changing PWK’s “vision” for some decades now. The computer generated models he gets for insanely complex crossovers are nothing at all like legacy PWK Klipsch but they just happen to work much better. I understand Roy is loyal to the vision of PWK but somehow he can change things around and it is approved whereas others do the same thing and it is not.

Klipsch and Roy themselves have admitted the old tech drivers were no good when they came out with the new ones for the revamped Cornwall 4 and the Heresy 4 and the new Forte. New drivers, new lenses in places, cabinet modifications and new crossovers. The end result is very good and they are light years ahead of the old style. My jaw dropped the first time I heard the CW4 and Heresy 4 and even though I make aftermarket tweeters I would sure not put them in these. Incredibly improved and also NOT PWK designed so whose vision is it now anyway? I say it is Roy’s vision and all that PWK legacy honoring stuff is just words.

What makes this kind of sad though is the demand that only pure unmodified Klipsch speakers are truly Klipsch speakers. Only JEM capacitors will give you that genuine “Klipsch” sound, whatever that is. Funny thing is that those of us who treasure our modified Klipsch speakers still consider them Klipsch speakers. But just what is a pure true blue Klipsch speaker sound anyway when Klipsch is busy changing the recipe that makes that sound? I figure the good bones a Klipsch speaker comes with allows for aftermarket tinkering, and a La Scala or Chorus for instance can go another 30 years or more and sound much better doing so with minor tinkering. Tinkering with Klipsch speakers goes back for decades on the Klipsch forums but there are now new rules to go by.

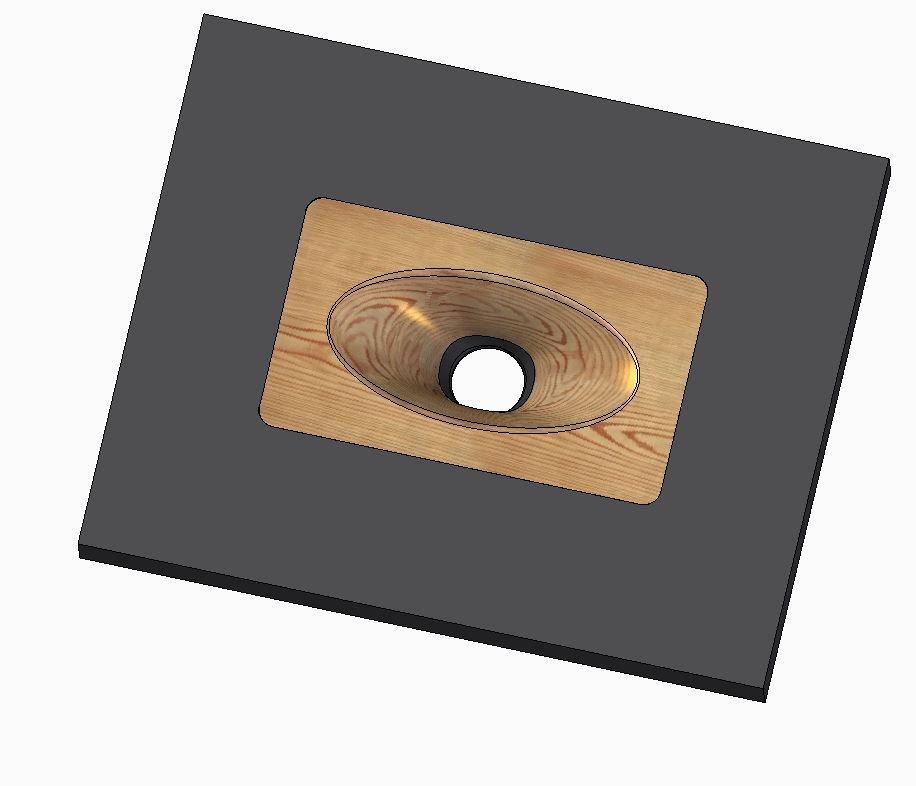

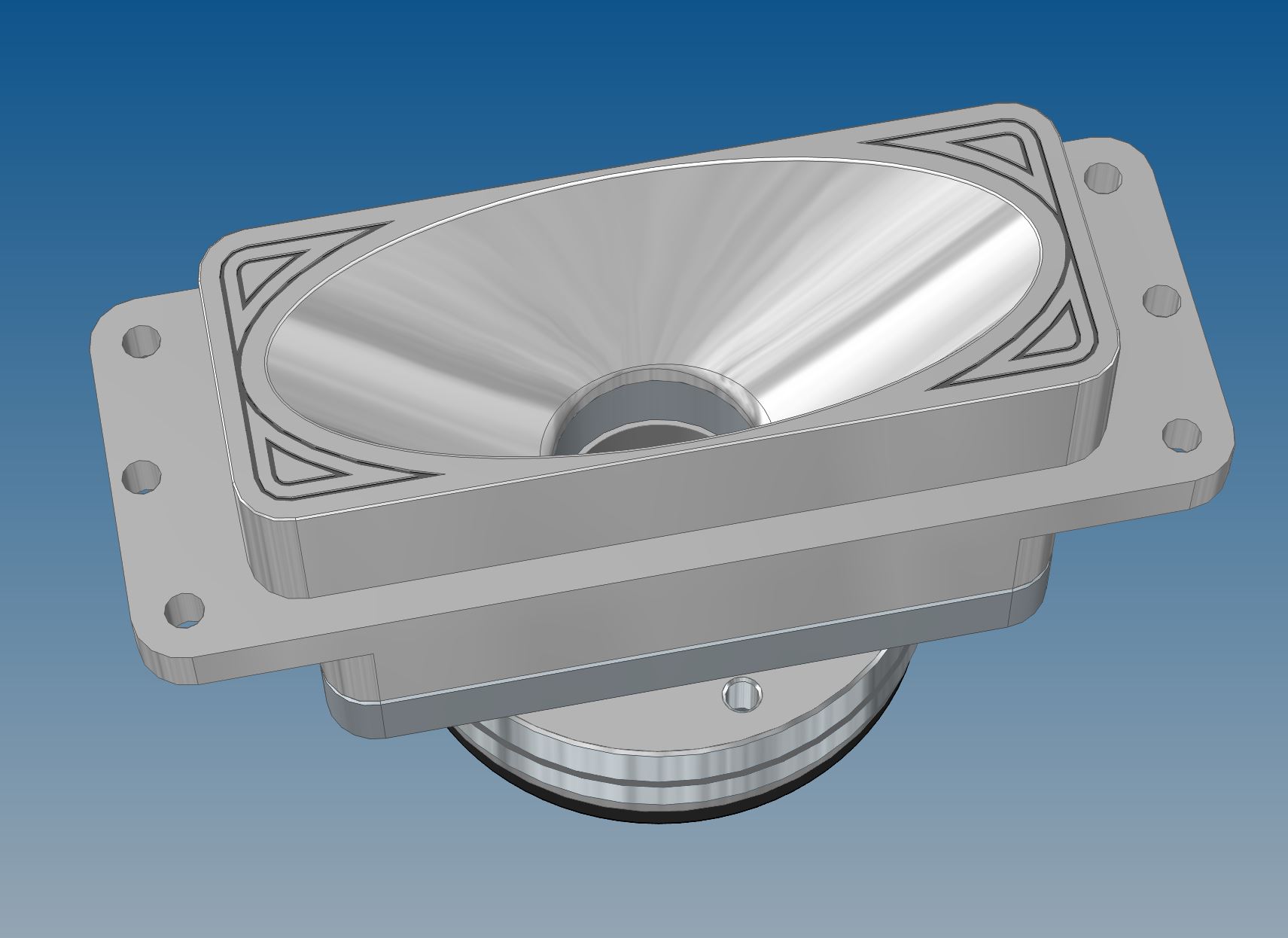

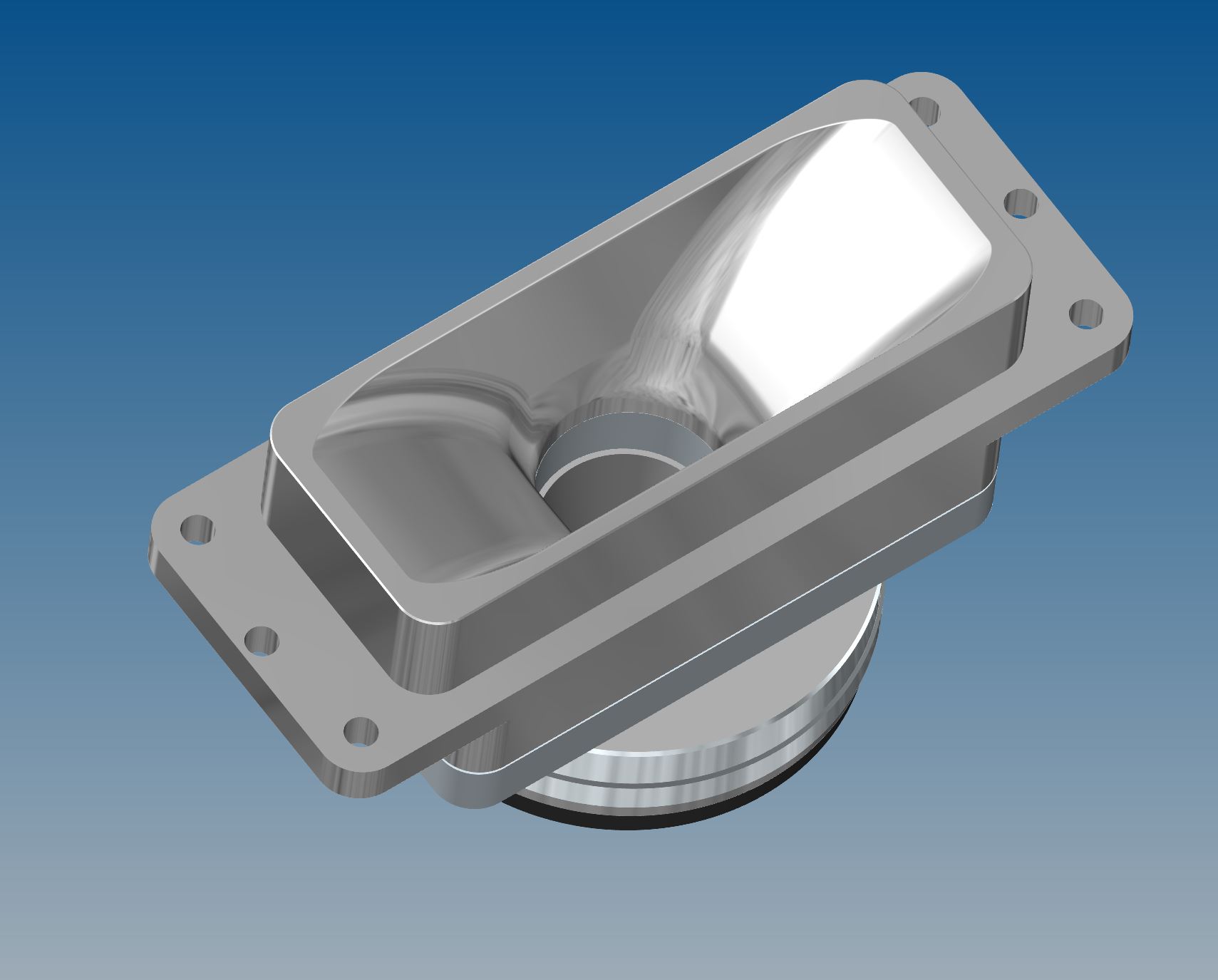

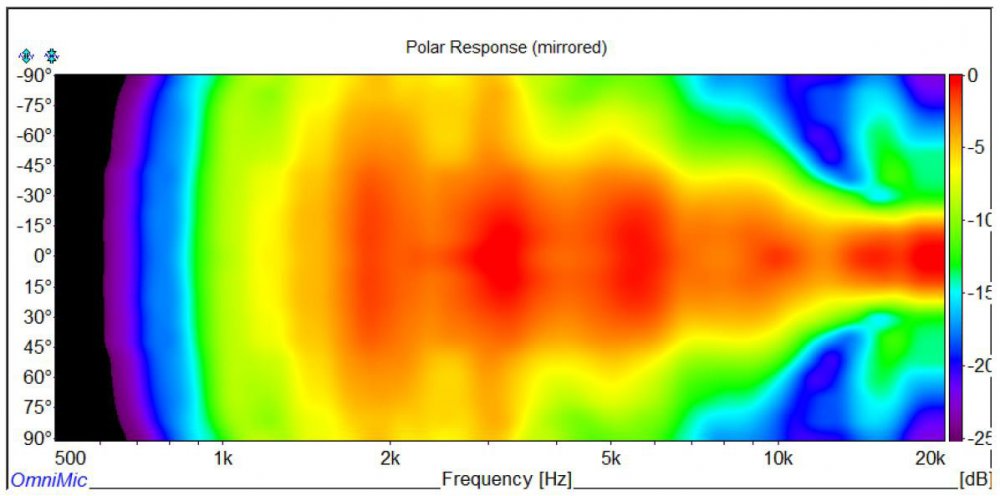

I had a thread about the new LMAHL V2 and SMAHL V2 started by another forum member that discussed the new V2 style and went into it in great length. I referred people to it on occasion when they wanted to see curves or why they were better. I figured Claude who was a forum member who graciously tested my ideas for me and other forum members who described what these new tweeters did for their speakers in their own words stated what they were and did better then me. Plus these were honest comments from others and not from the guy tooting his own horn just because he makes them. I am egocentric enough however to tell you patient readers I make the best aftermarket drop in tweeters for Vintage Klipsch speakers but let unsolicited buyer testimonies on EBay and the Klipsch forums do my horn tooting.

Much to my chagrin this thread was deleted. I found out when I referred someone to that thread and they could not find it. Well in looking neither could I because that now offensive “upgrade” thread had been deleted. So I did a search and found a link to the old post that while it did not work did give me a time frame and topic name to enter into the “Wayback Machine” site where I find the complete thread archived in all it’s glory.

If you do not know about the WaybackMachine it is a wonderful research tool you should know about. It saved the tweeter thread in a way Klipsch can’t delete and I have found old Pro Klipsch gear brochures from the 90’s there also that Klipsch had thrown away a long time ago with a past forum “upgrade” that trashed a lot of legacy data.

So, you have MAHL V2 questions there are once again answers.