Time alignment is something that people with La Scalas and KHorns have requested over the years. As a matter of fact the very first demand for free standing MAHL’s came from these Klipsch owners. As a result I have tinkered with various free standing MAHL’s for a while now. Mostly these are very limited production and most of the time are single unique sets only. I do my best to find figured wood and make these works of redeeming visual appeal as well as real audio quality improvement. Here is a set with Crotch Black Walnut and Black Locust live edge cookies.

My first effort at time aligning was forced on me with my Super MWM set which had a 108″ throat on the single fold bass bin. I had to use DSP for that and also to dial in the K-402 horn on top. The guys who were asking about free standing MAHL’s however were typically dealing with time aligning maybe 12″ at best. I could never hear any difference with a 12″ time alignment. With 108″ though there was a clear muddiness added when not time aligned so when these guys asked for MAHL’s for 12″ or less time alignment I just figured they could hear much better then I could and set about making some.

Now along the way in talking to other K-402 owners I find that almost all of them spent some time aiming those big horns radially and for vertical tilt. With a set in hand to play with I quickly found out that aiming was a real thing for best results.

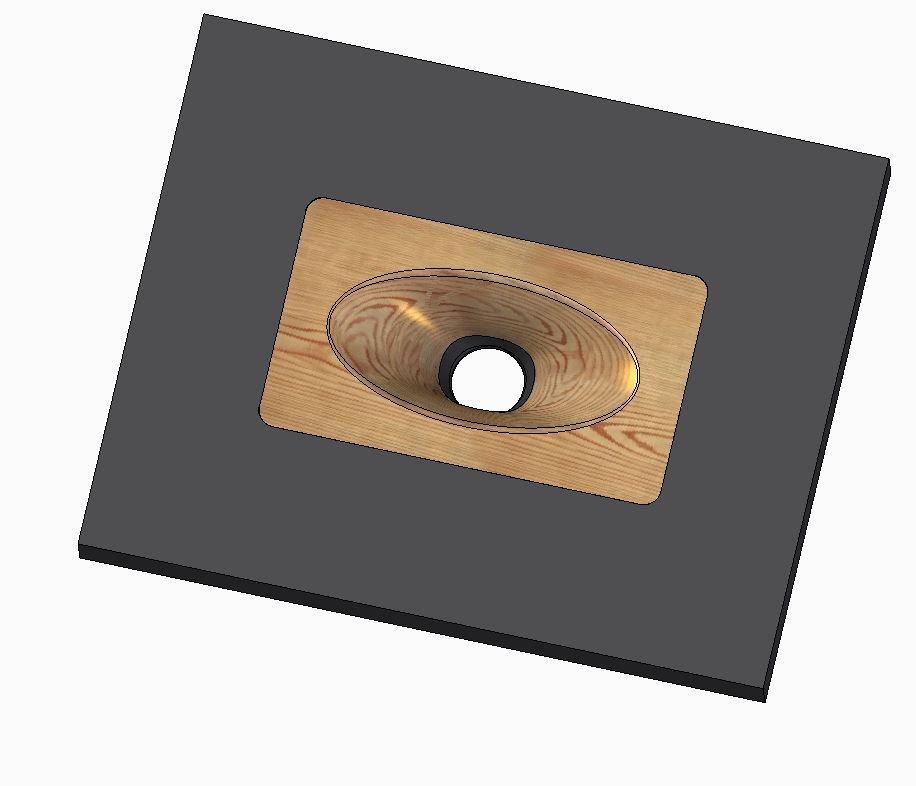

A year or two later found me working on my own complete two way speaker and I elected to do a two way. I used the same basic cavity shape for the SMAHL and LMAHL for the much larger 14″ x 7″ mouth 6.75″ deep solid wood horn and found that this basic tractrix cavity design scaled up really well.

Now insofar as time alignment went with this larger wood horn and the 12″ woofers the depth difference was negligible but rotating and tilting was something that clearly improved the sound.

So I go back to fiddling with looking at what customers had done with their free standers and they did not tilt but they all rotated to a sweet spot of their choosing. So I elected to design and cut free standing sets that did rotation only. This set of White Oak was my test bed for axial improvement. These are cut with the same exact proven cavity shape as the LMAHL’s and stand up high enough to clear any typical cabinet top reflections.

The axial adjustment alone made a real difference and I had to wonder how much aiming had to do with improved sound over less then a millisecond sound travel time would do with displacement from the front of the speaker.

The other really neat thing about these is that this idea works on any three way speaker they have been tried on to improve sound quality with a big enough flat spot on top. Lets face it, three sets of drivers on a fixed plane can never be aimed for that sweet spot. I will tell you that in my experience the HF has an influence on all the other drivers and until it is right nothing is right. When you have the HF dialed in correctly the bass sounds better as do the mids and you hear things you never heard before with those same speakers and aiming those tweeters is definitely a part of doing this. Go and look at comments on AudioKarma about the LMAHL or SMAHL and see what people say. Go to EBay and look at the feedback for the LMAHL V2 and SMAHL V2 tweeters.

It was entirely unexpected by me that the HF would improve it all and by a big margin but much to my utter delight it did. I remember telling people about this and they laughed at me. So I started a try it and see for various forum members. I would send them a set to try. If they did not like them I also paid to have them sent back so no one was out one thin dime to try. I never got one set back and what I got was how much are they and reviews that said the same thing I had been laughed at for claiming 😀

It is a diabolical trap for scoffers that they do not regret falling into.

I happen to really like high quality output. My very first customer for everything I do is me and I am in search of music quality that can make the hair stand up on your arms (the Super MWM) or bring tears to your eyes like Julia Fischer playing Vivaldi’s Four Seasons on my yet un-named but ready for production two way. First one going out to a customer in Louisville,KY later this month.

Here is the link to Julia’s Four Seasons. I downloaded the high res file and saved it. A trip through Audacity and using the high definition soundcard driver available for my Dell PC I use as a music server and this thing will stir your soul. By the way I generally make time for visitors and if you happen to be in the Nashville area with time on your hands drop me a line here ahead of time and you are welcome to stop in.